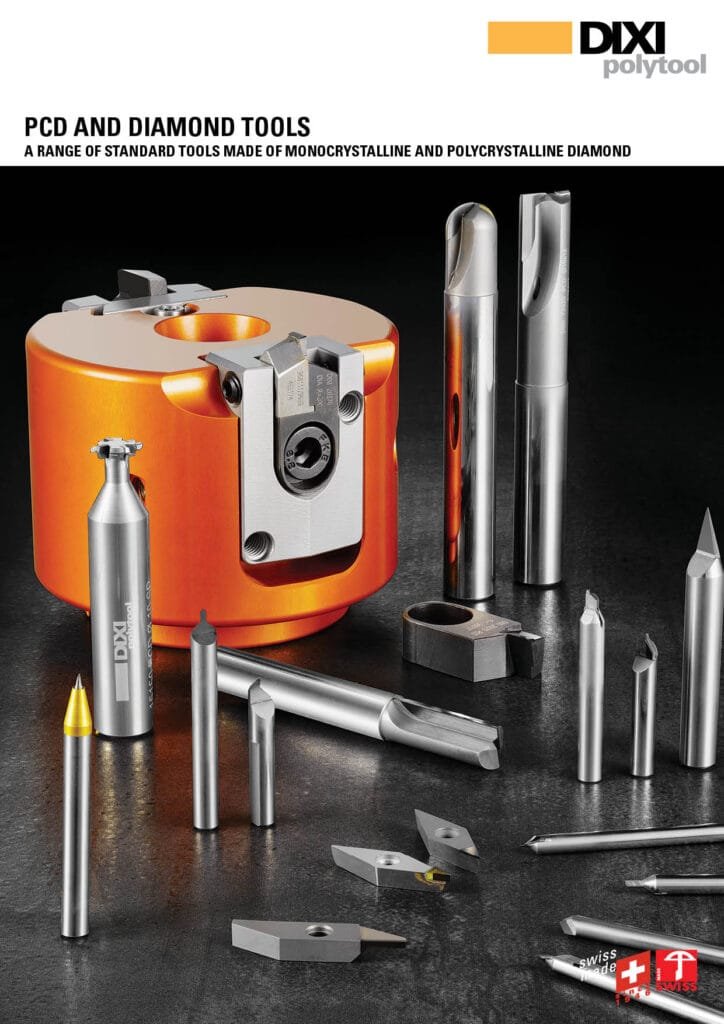

PCD & Diamond Tools

High-Precision Cutting Solutions for Abrasive and Hard-to-Machine Materials

Dixi Polytool’s PCD (Polycrystalline Diamond) and diamond-coated tools provide exceptional durability, precision, and surface quality, making them ideal for machining abrasive materials, composites, ceramics, and high-performance alloys.

These cutting tools offer superior wear resistance, extended tool life, and high-speed machining capabilities, ensuring maximum efficiency in aerospace, automotive, medical, and electronics industries.

Why Choose Dixi Polytool PCD & Diamond Tools?

Unmatched Hardness & Wear Resistance

Diamond tools are extremely resistant to wear, making them ideal for machining high-abrasion materials such as CFRP, ceramics, and hardened steels.

Extended Tool Life & Cost Efficiency

Compared to conventional carbide tools, PCD tools last significantly longer, reducing tool replacement costs and increasing productivity.

Superior Surface Finish & Precision

Optimized cutting geometries ensure excellent surface integrity, reduced burr formation, and minimal need for post-processing.

High-Speed & Efficient Machining

PCD tools allow for higher cutting speeds and optimized chip evacuation, reducing cycle times and improving efficiency.

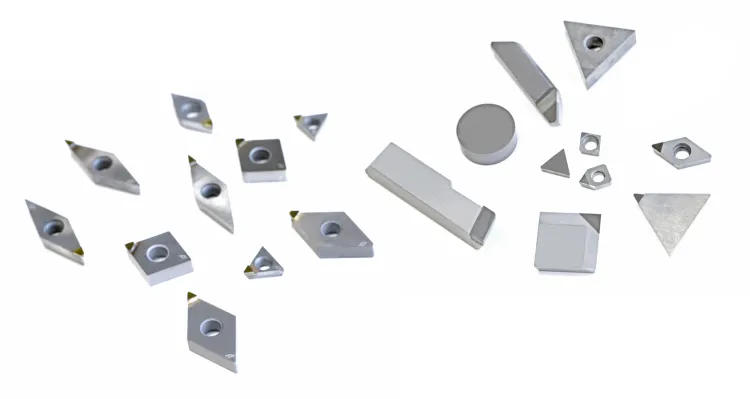

Specialized PCD & Diamond Cutting Tools

1. PCD End Mills

Designed for high-speed milling of non-ferrous and composite materials

Available in full PCD or PCD-tipped variants

Ideal for CFRP, graphite, aluminum, and titanium machining

2. PCD Drills & Countersinks

High-performance drilling solutions for composite materials and aluminum alloys

Minimized delamination and superior hole quality

Through-coolant options available for enhanced chip evacuation

3. Diamond-Coated Tools

Perfect for hard and abrasive materials such as ceramics, tungsten carbide, and hardened steels

Longer tool life and better wear resistance than conventional coatings

Ideal for micro-machining applications

4. PCD Reamers

Precision reaming solutions for tight tolerance applications

Exceptional surface finish and dimensional accuracy

Reduced heat generation for longer tool life