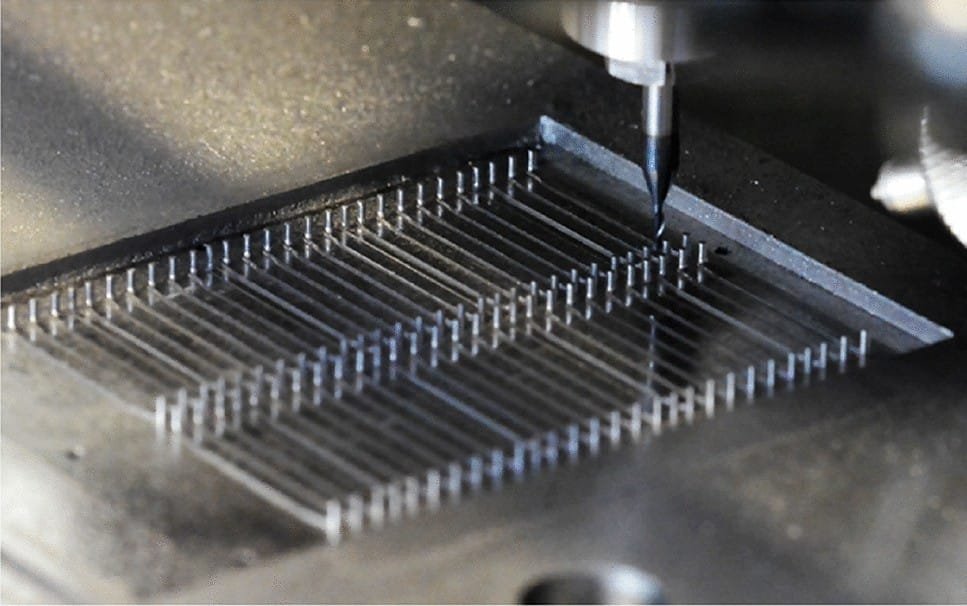

Micro milling has progressed from experimental labs to full-scale production, driven by the need for intricate features in medical devices, optics, and microfluidics. Today’s machines routinely handle tool diameters below 0.1 mm, enabling channel widths of just a few microns. As part counts shrink and tolerances tighten, manufacturers are demanding surface finishes and geometries once thought impossible.

Swiss Engineering: Precision Built In

Swiss-built micro milling centers integrate innovations at every level of the machine. Hydrostatic guideways eliminate mechanical play, while magnetically levitated spindles reduce bearing friction to near zero. Temperature-controlled oil circuits stabilize the entire structure within ±0.2 °C, preventing thermal drift over long production runs. These design choices translate directly into sub-5 µm positional accuracy without post-process rework.

Advanced Toolholder Technologies

- Active Vibration Damping: Piezoelectric dampers sense chatter frequencies and inject counter-vibrations to preserve tool integrity.

- Micro-Collet Systems: Proprietary taper-lock collets ensure clamping run-out under 0.3 µm, even at 80,000 RPM.

- Quick-Change Adapters: Minimize downtime by swapping micro-end mills in seconds, without sacrificing concentricity.

Optimizing Toolpaths for Minimal Deflection

Proper CAM strategy is critical. Steep-fine passes with high lead-in angles distribute cutting forces evenly, reducing deflection by up to 40 %. Combining adaptive clearing routines with dynamic feedrate control keeps engagement constant, preventing sudden tool overloads that can degrade dimensional accuracy.

Material-Specific Considerations

- Inconel & Titanium: Use corn cob-type chip breakers to prevent serrated cutter marks and heat buildup.

- Glass & Ceramics: Apply ultrashort pulse laser texturing to the tool flank for improved lubrication retention and reduced micro-cracking.

- Polymers & Composites: Opt for diamond-like carbon (DLC) coatings to avoid material adhesion and ensure edge sharpness.

Temperature and Vibration Management

Even minute temperature variations can warp a micro part. Swiss systems often incorporate embedded fiber-optic sensors in the spindle housing to monitor heat spikes in real time. Coupled with active damping tables, these insights allow on-the-fly compensation, maintaining geometric integrity even during extended cycles.

Quality Assurance: Inline Metrology and Traceability

Integrating laser triangulation or capacitive probes directly into the machine enables verification of critical features without removing the workpiece. Data is logged and matched to a unique serial number, creating a traceable record of each micro component’s dimensional compliance—essential for regulated industries like medical implants and aerospace sensors.

Integrating Swiss Micro Milling into Your Production Line

Adopting Swiss micro milling starts with a detailed process audit: map out critical dimensions, cycle times, and batch sizes. Next, pilot runs on representative parts will fine-tune parameters. Finally, leverage remote monitoring platforms to track spindle health, tool wear, and environmental factors—turning real-time analytics into continuous improvement loops.

Conclusion & Next Steps

Swiss micro milling represents the pinnacle of precision machining, delivering unmatched tolerance control, surface quality, and process consistency. By combining advanced machine design, cutting-edge tooling, and inline metrology, you can push product capabilities into truly microscopic realms. Ready to take your manufacturing to the micron level? Contact Precision Tool Systems today for a customized demo and live cutting trials.